Precision Redefined: Revolutionary R&D for Revuelto Exhaust

Think building a top-tier exhaust system is just trial and error? Think again. ARMYTRIX’S R&D team harnesses cutting-edge 3D technology to craft the ultimate Revuelto exhaust system, leaving outdated methods behind. For instance, it’s engineered for mind-blowing performance and a seamless fit that rivals factory standards, setting a new benchmark. Curious about how 3D technology transforms exhaust design? Dive into the details below!

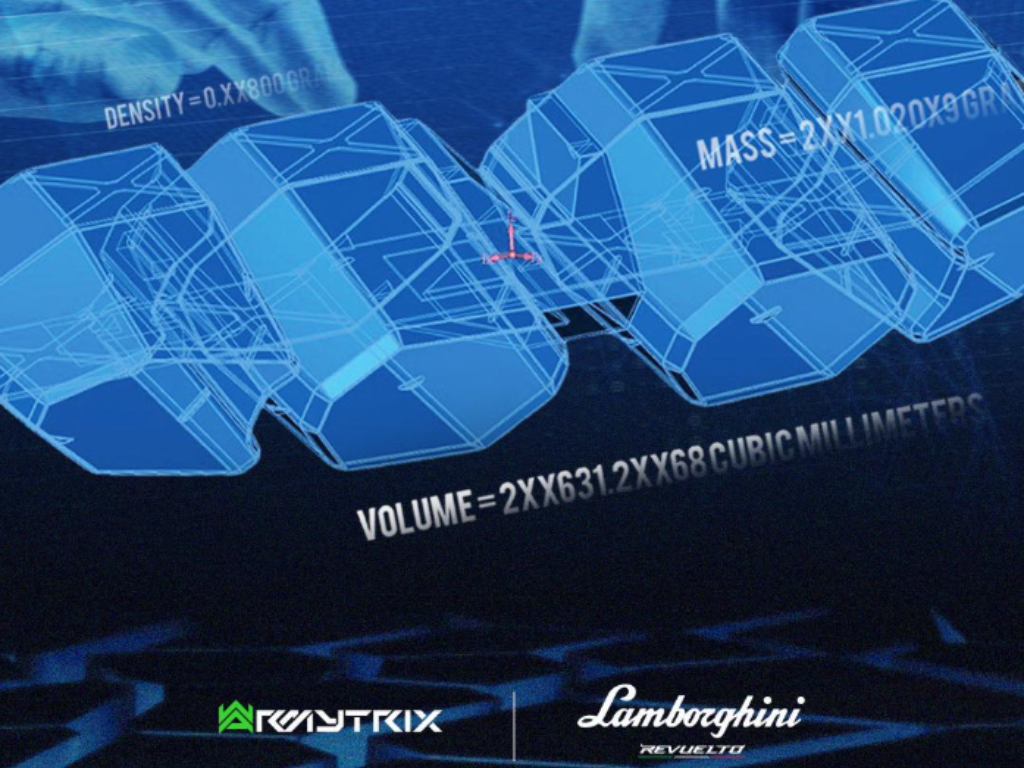

3D Scanning Mastery: Precision for Revuelto Exhaust System

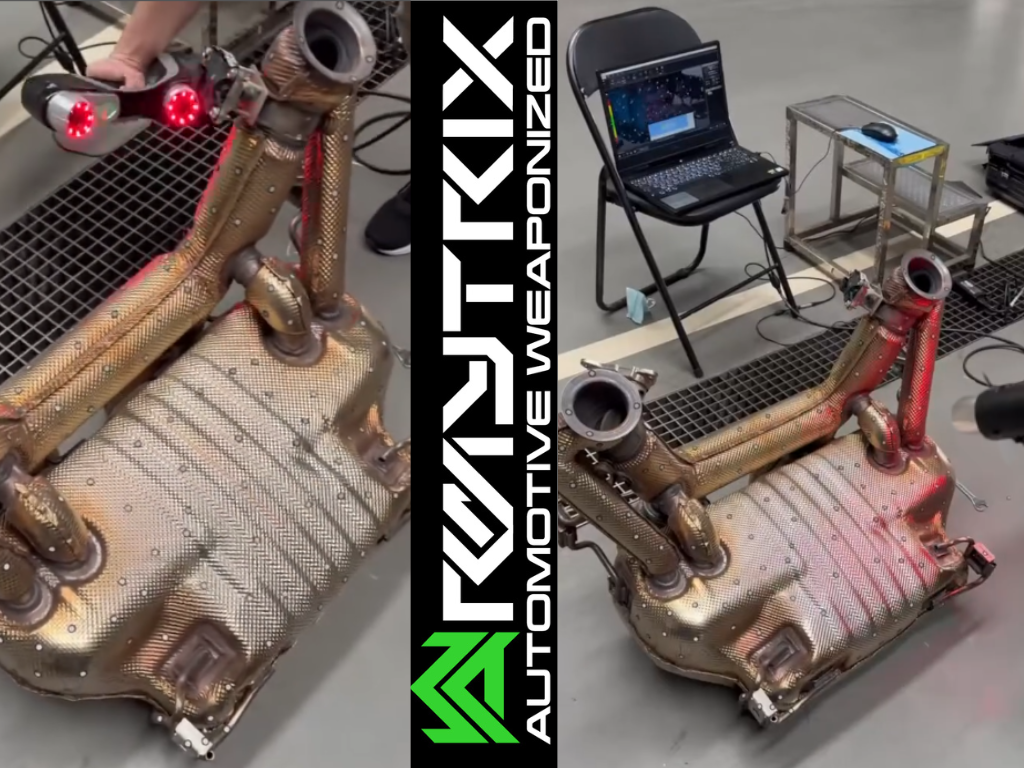

Our process begins with state-of-the-art 3D scanners, meticulously capturing the Revuelto’s complex undercarriage. Unlike traditional handcrafted methods—relying on trial-and-error cuts and welds—our 3D scanning technology ensures pinpoint accuracy. In fact, this isn’t just about keeping pace with trends; it’s about showcasing ARMYTRIX’S commitment to innovation and precision in exhaust system design.

Digital Precision: 3D Technology in Revuelto Exhaust Design

Why 3D Technology Boosts Revuelto Exhaust Precision

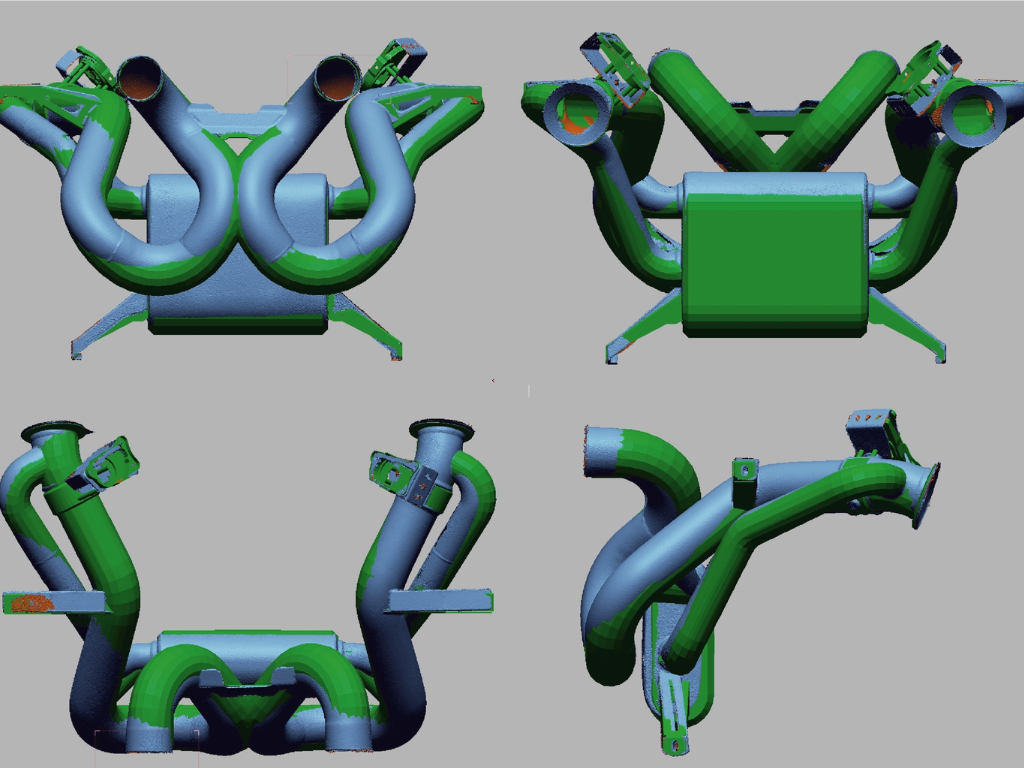

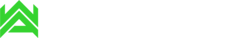

Using this data, we create spot-on 3D models that replicate every curve and contour of the Revuelto. Why choose 3D modeling? Because it delivers unmatched accuracy and flexibility, outshining conventional techniques. As a result, our team can identify flaws early, adjust designs instantly, and perfect every detail.

Crafting the Revuelto Exhaust System with 3D Tech

For the Revuelto exhaust system, we designed the exhaust pipe in 3-inch diameters to optimize exhaust flow efficiency, and a 70-degree angle at the X-pipe to have soundwaves merge—producing a steady, powerful roar. Thus, this fusion of advanced tech and precision elevates the Armytrix exhaust system to exceptional heights.

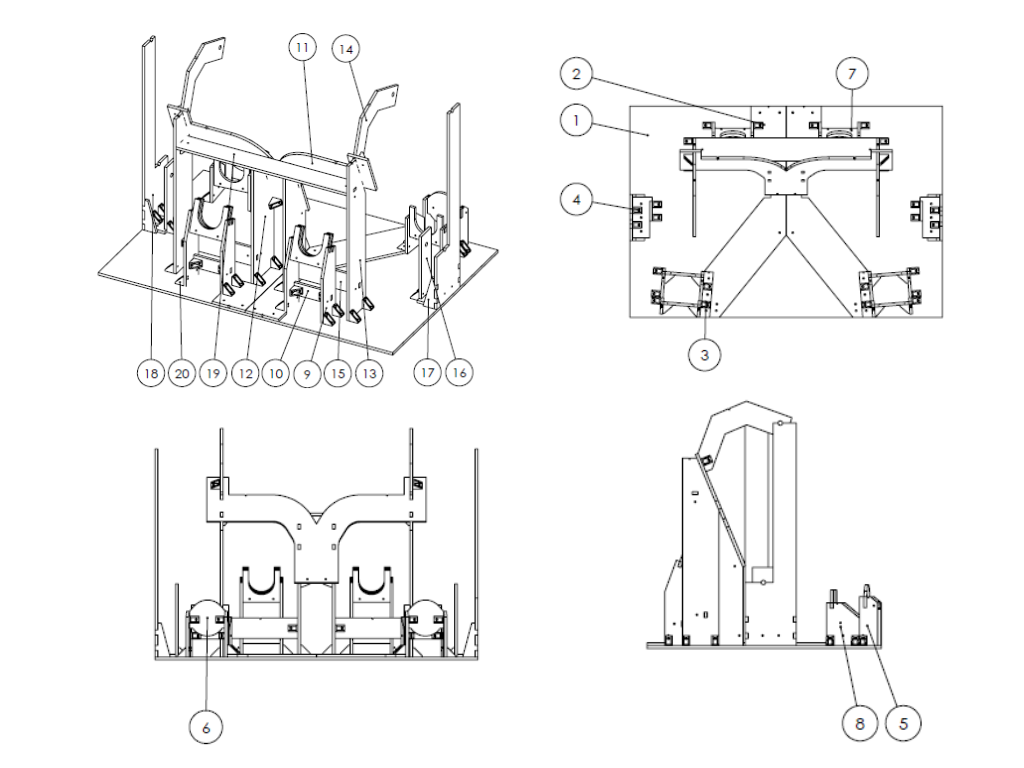

Jig Perfection: 3D-Designed and Printed for Fit

We use advanced 3D modeling to craft custom jigs, validated through 3D printing for a flawless fit. Designing these jigs requires precision—down to millimeters in dimensions and tolerances. For example, take the X-pipe baseplate and X-pipe bracket: even a minor mismatch could cause gaps or misalignment, affecting airflow and quality. However, with 3D technology, we eliminate these risks, ensuring the Revuelto exhaust system performs at its peak.

Double-Checked Excellence: Post-Production 3D Scanning

Once the ARMYTRIX exhaust system is complete, we perform post-production 3D scanning to verify every specification meets our rigorous standards. Consequently, this final step guarantees seamless integration with the Revuelto, delivering unrivaled performance and a perfect fit. At ARMYTRIX, precision isn’t a guess—instead, it’s a promise, rooted in our dedication to quality and innovation.